Situation and development trends in the sector of CNC cutting machines

CNC cutting machines only outwardly do not change. In fact, this sector is strongly based on innovations which are still implemented in new devices. However for this time there is no chance to appearing new cutting technology, development focuses on optimizing of parameters which decide about attractiveness of device for user. The best solutions are included by patents because they warrant achieving of uniqueness of producer and have influence for competitors.

Tracking changes taking place in the best producers offer which are available on polish market, there is simply to guess CNC cutting machines sector divides on two groups:

- entry machines,

- high-end machines.

CNC cutting machines producers in Poland

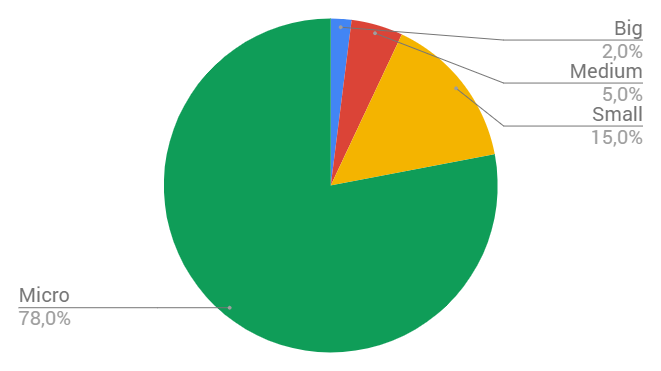

Current situation in CNC cutting machines can be characterized by many indicators. There are for example: machines quantity, producers amount or sector profitability. In 2014 there were 335 companies which declared basic activity in cutting machines sector. This number was 7% higher than year before. According data from Central Statistical Office there are generally micro companies (78%). On drawing 1. there is presented companies characteristic according of employees quantity.

Drawing 1. Producers of machines and mechanical tools in Poland in 2014 (source: Central Statistical Office)

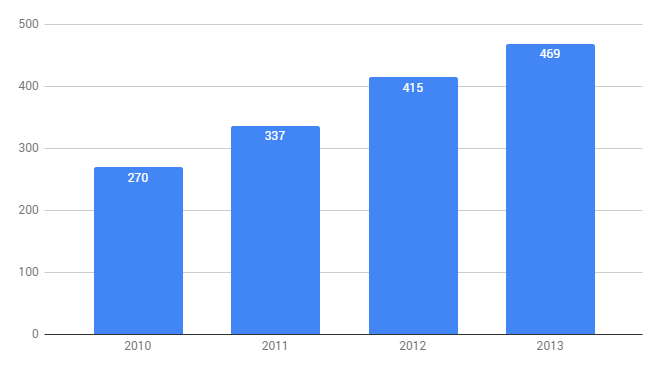

Data about profitability indicate stability of good financial condition in sector. Scores presented in “Monitor Polski” in 2010 indicated revenues with a value of approx 700 mln zl and profitability was 11%. Presently data from Eurostat about machines producers market indicate revenues value 1720 mln zl. With reference to perspective of metal tooling machines sector in Poland, it is characterized by dynamic sales growth and big export participation. According data from Central Statistical Office production of CNC cutting machines also grows (Draw. 2).

Drawing 2. Production of CNC metal tooling machines in 2014

Tooling machines sector in relation with other industry sectors

With reference to Polish industry processing, generally, sector of CNC tooling machines is about 1,5% of value. It is characterized by lower than average added value and it is less than 1% of total industry production value in Poland. However, you should be aware this statistic does not include sector variety and its major representatives. This sector scores may be reflected in many other branches of industry.

Market analysis - characteristic of researched companies

In September 2017 there was made research for specifying condition of cutting machines market. There specified also how often there is used each cutting technology in industry companies in Poland. Research consisted of questionarring of chosen companies. Questionnaire was sent via e-mail and traditional mail for companies typed from maintained and still actualized database by Welding Institute. There obtained more than 100 answers. Companies which took part in research are in 15% small companies, 29% middle companies, 56% large companies. Questionnaires results were base of more than half of following analysis. Among all of analized companies each one implemented at least one of specified in table 1. quality system or permission system. Almost 70% of companies implemented ISO 9001 system and ISO 3834. Others implemented in companies norms are presented in table 1.

Tab. 1. Used in company system of quality of permission

| Quality system | Amount of implementations in researched companies [%] |

| EN ISO 9001 | 70% |

| EN ISO 3834 | 70% |

| EN 1090 | 29% |

| DIN EN 15085 | 17% |

| EN ISO 14001 | 20% |

| N-18001 | 13% |

| inne | 5% |

Market analysis - cutting technology vs other technologies

Table 2. presents popularity of welding technologies and similar used in analyzed companies. Generally used cutting technology in researched companies is thermal cutting (about 36%) and laser cutting (more than 12%).

Tab. 2. Welding and similar technologies used in companies

| Used technology | Number of implementation [%] |

| Welding MIG/MAG | 71% |

| Welding TIG | 57% |

| Thermal cutting | 35% |

| Manual welding EO | 32% |

| Arc welding | 18% |

| Surfacing | 18% |

| Welding | 13% |

| Laser cutting | 12% |

| Soldering | 10% |

| Braze welding | 8% |

| Induction heating | 7% |

| Bonding | 5% |

| Other | 7% |

These high values are reflected in quantity of bought devices by researched companies in last 5 years. On first place there are devices for MIG/MAG welding (65%), on second there are devices for TIG (48%), while on third place are devices for plasma cutting (almost 19%). There were also bought devices for oxygen cutting (10%) and for laser cutting 2D (8%). In case of robotic solutions and amount of robots used in welding and similar processes, among analyzed companies the most popular were welding robots for MAG welding (36%), on second place there were robots for cutting (16%). In case of technologies with laser using, cutting was on first place (87%).

Development of cutting machines of materials is heading towards product quality increasing, efficiency increasing but everything is changing with keeping care for economic factors and for environment. Besides of need for automatic solutions in range of cutting technologies, till this time high investment price was independent and reason for making decision of investment. At this moment there is improvement visible in this range.

Entry level cutting machines are dedicated primarily for micro, small and middle companies which are 99,8% of all companies. They have only basic functions and are characterized by small working size. But they keep high efficiency by suitable optimized parameters. Additional advantage of entry level cutting machines can be their expand and extension of their functionality. This option is especially useful for companies which develop but are not ready for total change of machine park elements.

High-tech machines are the mostly interest of big companies, units of hard industry and companies functioning in range of narrow specialities which need the best solutions. These devices are characterized by the strictest parameters values and often have different kinds of hybrid solutions.

Among both machines groups there are developed new solutions for parameters optimization. Presently this is group of several dozen features which value can be conditioned by legal provisions, customers individual needs or desire of getting suitable value of another, conjugated parameter. There are specified below parameters which the mostly are object of customers interest:

- laser power - this parameter exist only in laser cutting machines but it well presents development of innovations in CNC machines sector. In 2016 during ITM Mach Tool exhibition in Poznan there was presented laser cutting machine with 12 kW power that is able to cut 60 mm plate. There was innovation on a global scale. Year later during the same exhibition another company presented laser cutting machine with 15 kW power,

- minimal time needed for technologic production preparing and for rearming - every minute devoted to preparing actions makes less time that stays to using for production,

- ergonomy of service and software - this parameter is really hard to be expressed in numerical values. Measure there can be time needed for operator and technologist training but it is not exhaustive measure. Important is also software interface and arrangement of machine elements that makes possible to freely control it,

- influence for natural environment - it is presently often topic of subject of legal regulations. This issue consists of many elements. Some of them are described below,

- electric energy consumption - reduction of consumption is subject of interest because of two reasons: because of environment and because of costs which are generated during consumption,

- heat emission - parameter is reduced through with reducing of electric energy consumption,

- noise emission - unneeded phenomenon both from the point of view of nature and employees. It is reduces primarily by attenuators. Strives to construct quieter mechanism,

- influence for human health - it us also unmeasurable parameter because it is not possible to estimate or measure safety. Machine should be safe. Safety is provides primarily by technologic solutions which protect against accidents, especially in working area,

- minimal collision amount - using of different kind of sensors and other technologic solutions,

- development of control systems by: increasing of control systems calculation possibilities, extension of control systems capacity for example by support for automation of the machining station, matching to the requirements of technological data management within Industry 4.0 idea,

- cutting speed - one of the most important parameters. Increasing cutting speed translates to machine performance,

- repeat accuracy - manifests by possibility of getting identical cut parts which are in accordance with given data,

- construction - understood as matching to customer expectations, size reduction, stability increasing and others,

- errors amount - parameter adjusted with developed methods of errors compensation. They serve generally for: increasing of components accuracy, providing of suitable assembling of cutting machine, heat sources minimizing and reduction of heating influence.

Actions taken for improvement of described features results in implementation of new solutions in CNC cutting machines. Some of innovations like described machines with very high laser power became “visiting card” for companies which used solution as first.

Another example of innovation that became important element of producer offer is also plasma cutting head Vortex 3D. It presently works as Vortex 3D FL (device is improved by reducing weight and higher dynamics). Most of used till 2015 solutions in CNC cutting machines made possible to cut plates and pipes at right angle. But often there was necessary to bevel edges for welding. Developed, patented by Eckert company plasma cutting head Vortex 3D wit RACT system (Real Adjusted Cutting Trace) was in 2015 until today one of the most modern devices on market. Cutting head allows rotation +/- 540° that provides cutting out of complicated contours without interruption machining. It can be also smoothly tilted during tooling up to +/- 47° from vertical plane. It allows then for very precise beveling and chamfering of sheets during one cutting process.

It deserves attention also Drop&Cut system that is a tool that allows for efficient using of cut material. On controller display, during cutting process, operator can live control, position and match specific plate section. New element production is based on the principle of using entered in cutting machine system new cut part geometry. It is enough to move the virtual geometry of the cut part with the finger to the remaining material. Due to constant live transmission, outline of contour of cut part can be flawlessly made of remains of sheet from previous process.

Besides division for compact and high-tech machines, there is probably inevitable to use Industry 4.0 elements. These elements will be present in both machines groups.

There is also observed trend for hybrid machines construction. They are functional connection, for example cutting machine, drill, punch marking machine within one device or connection within technologies. Example of this machine is CNC cutting machine Opal Waterjet Combo produced by Eckert that is able to cut with plasma and with water within one cut element.

Market of CNC cutting machines is constantly changing. It deserves recognition polish brands become more and more popular and their products more and more willingly buy by foreign companies. Machines offer will undergo an ever increasing division for compact and high-tech machines. New innovations will focus on parameters optimization. More and more visible will be also influence of Industry 4.0. Changes will be faster. Constructors still overcome barriers that until recently seemed unbeatable. The only reliable indicator of changes will be customers expectations. Generally new products will be the mostly based of individual customer needs and developed especially for them.