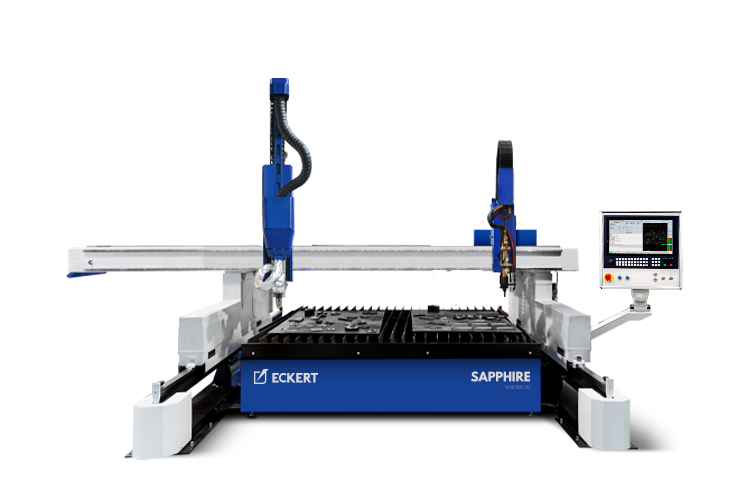

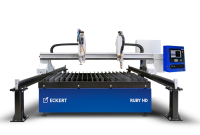

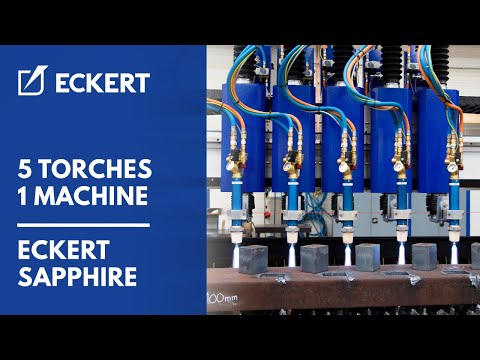

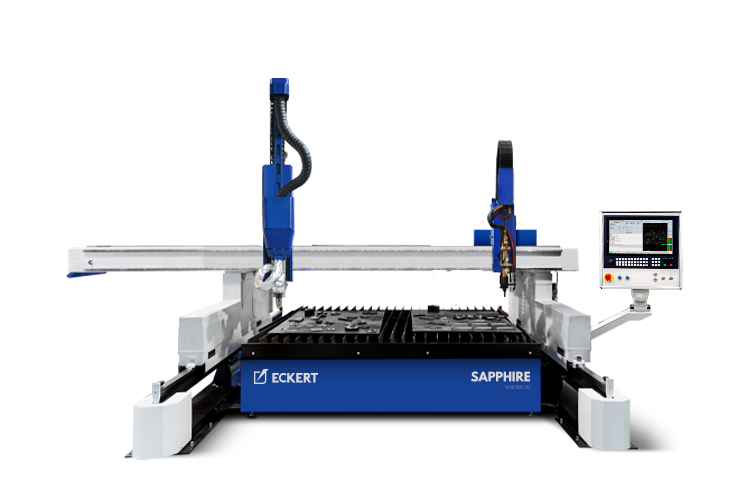

Sapphire

Robust construction and high productivity for production in perfection. One of the most awarded CNC cutting machine in its class.

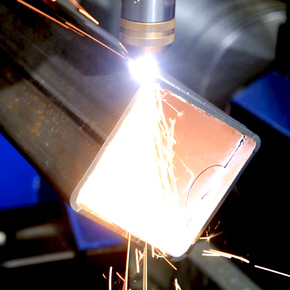

Plasma

Oxygen

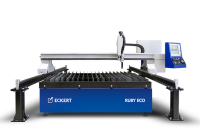

Sapphire

Robust construction and high productivity for production in perfection. One of the most awarded CNC cutting machine in its class.

Plasma

Oxygen