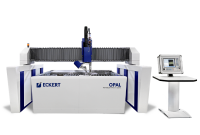

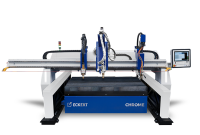

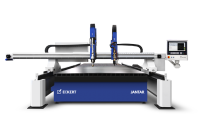

Opal Waterjet Combo

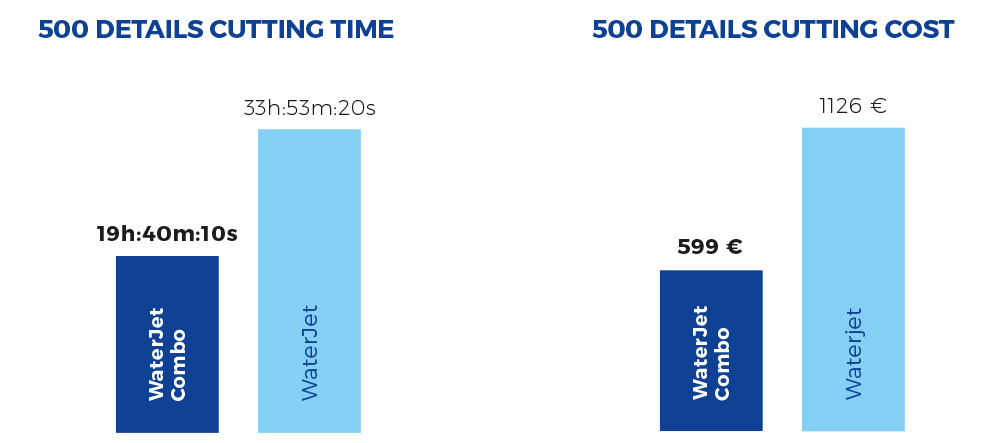

Innovation, accuracy and cost efficiency. Patented combination of waterjet and plasma.

Water

Plasma

Opal Waterjet Combo

Innovation, accuracy and cost efficiency. Patented combination of waterjet and plasma.

Water

Plasma

.jpg?w=210&h=210&f=crop)

.jpg?w=210&h=210&f=crop)

.jpg?w=210&h=210&f=crop)

.jpg?w=210&h=210&f=crop)

.JPG?w=210&h=210&f=crop)

.JPG?w=210&h=210&f=crop)

.JPG?w=210&h=210&f=crop)