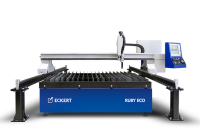

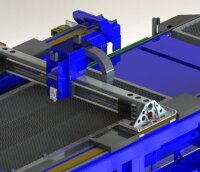

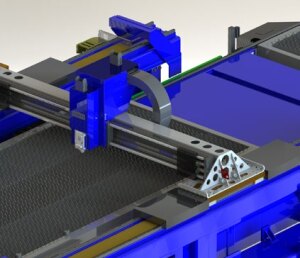

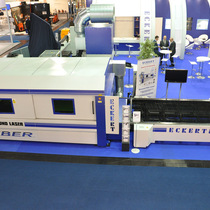

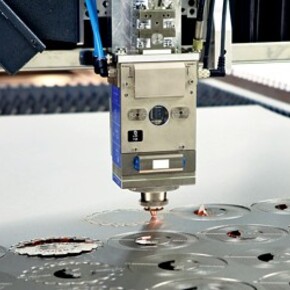

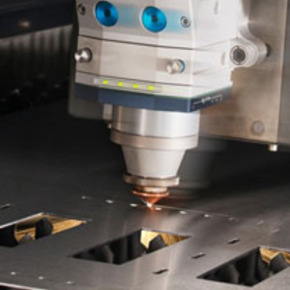

Diamond Fiber Laser 2

Future in laser cutting. High dynamics and the best cutting precision.

Laser

Diamond Fiber Laser 2

Future in laser cutting. High dynamics and the best cutting precision.

Laser