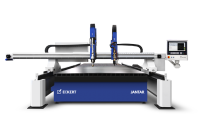

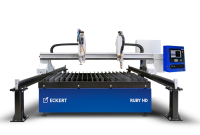

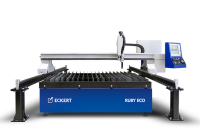

Onyx

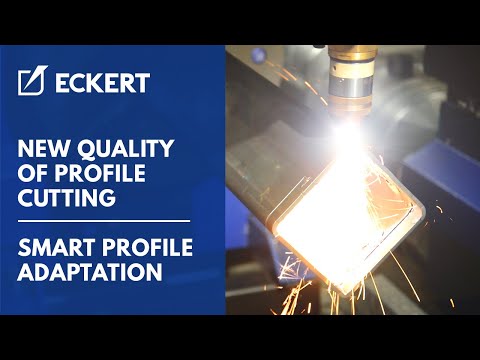

Modern construction and innovative technological solutions. Unique ergonomy of work and atractive design.

Plasma

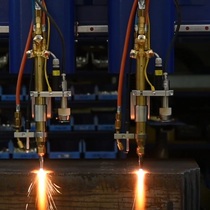

Oxygen

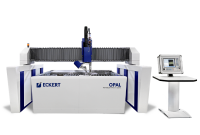

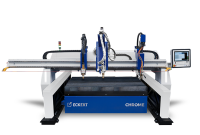

Onyx

Modern construction and innovative technological solutions. Unique ergonomy of work and atractive design.

Plasma

Oxygen