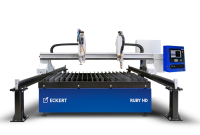

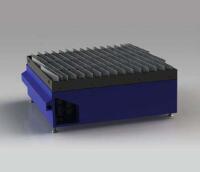

Ruby ECO

Economical solution for small and middle sized companies. Exceptional ergonomics and high class equipment from prestigious suppliers.

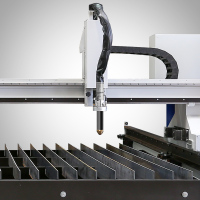

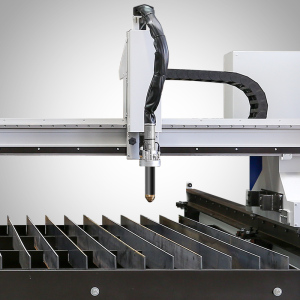

Plasma

Ruby ECO

Economical solution for small and middle sized companies. Exceptional ergonomics and high class equipment from prestigious suppliers.

Plasma