Chrome

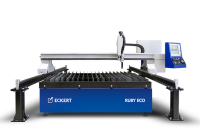

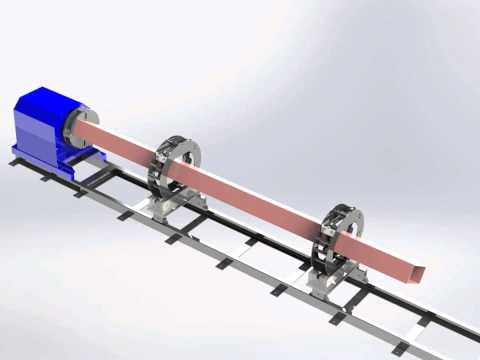

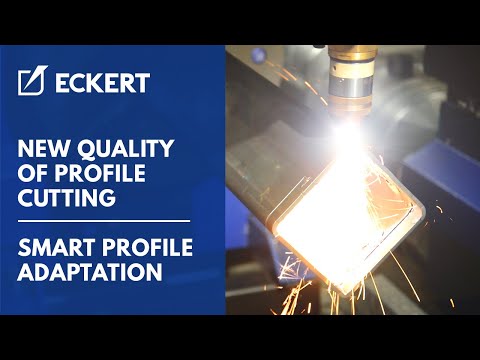

Explore new generation of dynamics and precision in CNC plasma cutting.

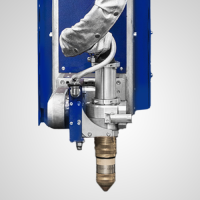

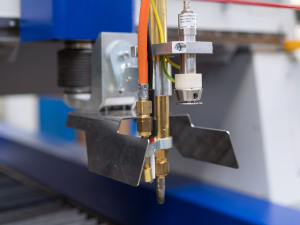

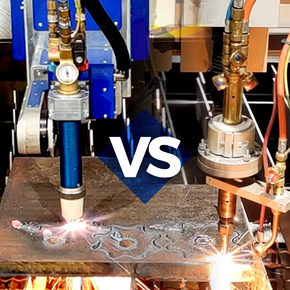

Plasma

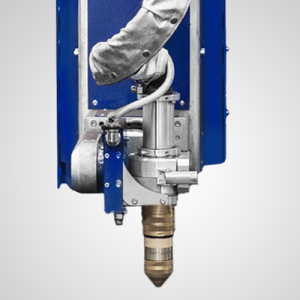

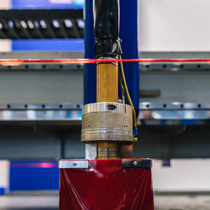

Oxygen

Chrome

Explore new generation of dynamics and precision in CNC plasma cutting.

Plasma

Oxygen